Whether you’re inexperienced with a liquid filling or you’ve hit a production ceiling and need to replace your filling machinery, you’ve undoubtedly discovered that a search on Google for a liquid filling machine just makes you feel more perplexed and hesitant than before. The liquid filling business has done an excellent job over the years of providing a wide variety of filling machines that are highly customizable while providing little to no assistance or explanations to help you get around and make wise judgments. This intentional strategy has benefited the producers of filling equipment since it frequently prompts phone contact from distressed and vulnerable potential customers.

We want to remove the uncertainty today & provide you with seven important factors to take into account when choosing your future liquid filling machine.

Cost

Cost is elusive across the board in the liquid filling sector, and it is rarely if ever, discussed in blogs or other online teaching materials. However, we are aware that it is an important factor, particularly for businesses with little resources.

The best piece of advice we can give you in this situation is to make sure you’re starting to work with a filling manufacturer who’s really eager to comprehend your special production requirements and budgetary constraints to make sure the solution you’re investing in provides you the maximum return on your money in the near term and also is designed as part of an effective implementation that will grow with your company to ensure a maximum return in the long run.

Speed of Filling

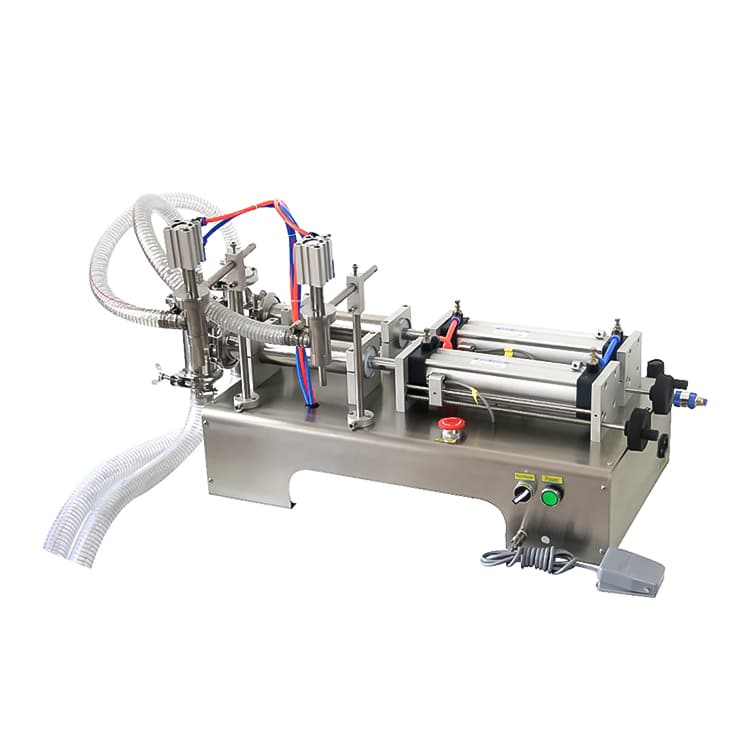

You must agree that faster is better. A tabletop machine including 1 or 2 fills heads filling on a rate measured in bottles each hour is not going to be of much use if your manufacturing demands really high volume output (BPH). The market for completely automated filling lines that can produce multiple bottles each minute (BPM) and handle filling, capping, and labeling all at the touch of a button is likely to exist if cost is not a concern and you want to optimize production.

Container’s Type

There are countless sizes and varieties of containers available at the moment, and the particular type you choose for your items can have a big impact on the kind of equipment that will fill it most effectively. It’s a terrible day when you find out that the off-the-shelf filling machinery you just bought won’t easily fit the containers you’ve chosen since this is a factor that beginners to the liquid packaging market sometimes miss.

Principle of Filling

Choosing between fill-level filling machines and a volumetric filling machine is a crucial consideration when choosing the finest filling machinery for your application. Two factors are taken into account while deciding this:

Q1. What kind of liquid substance are you filling, question one?

Q2. How do you envision your finished product appearing on store shelves?

Volumetric Filling

Despite changes in the form or size of the containers that might normally cause the liquids to seem to be at various levels, this sort of filling machine provides an exact volume of the liquid within each container. Because volumetric fillers need specialized equipment for timing, calibration, & balancing, their operating costs are frequently higher than fill-level machines’. When liquid should be packaged in exact doses or when reducing waste is essential owing to the high cost of a particular product, customers that use volumetric filling machines often view this as a good investment.

Fill Level Filling

These fillers, also known as cosmetic fills, ensure that each bottle is filled to the same level even when the amount of liquid in each bottle varies. Glass bottles against plastic (PET) bottles might be the most appropriate illustration of this use. 8 ounces of liquid inside one bottle might not have the exact same FILL LEVEL as another since blown-glass bottles almost never have the same consistency from bottle to bottle.

Support

It might be challenging to choose the best solution for you based just on a flashy (or not so flashy) site when you’ve been researching liquid packaging choices since there are many to consider. We are aware that the machinery we produce is an expensive investment, therefore you want to be sure you can rely on the company you work with this for your filling requirements. As a result, we’ll advise you to think about a few less obvious elements as you move around the area.