Effective asset tracking management is a significant priority for manufacturers and suppliers in the automotive industry. RFID in automotive has drastically improved asset management and enhanced the production phase. This blog post will explain the eight noteworthy asset-tracking trends in RFID in the automotive industry, followed by how RFID can improve resource management, leading to a more efficient and effective business.

How Does RFID in Automative Works?

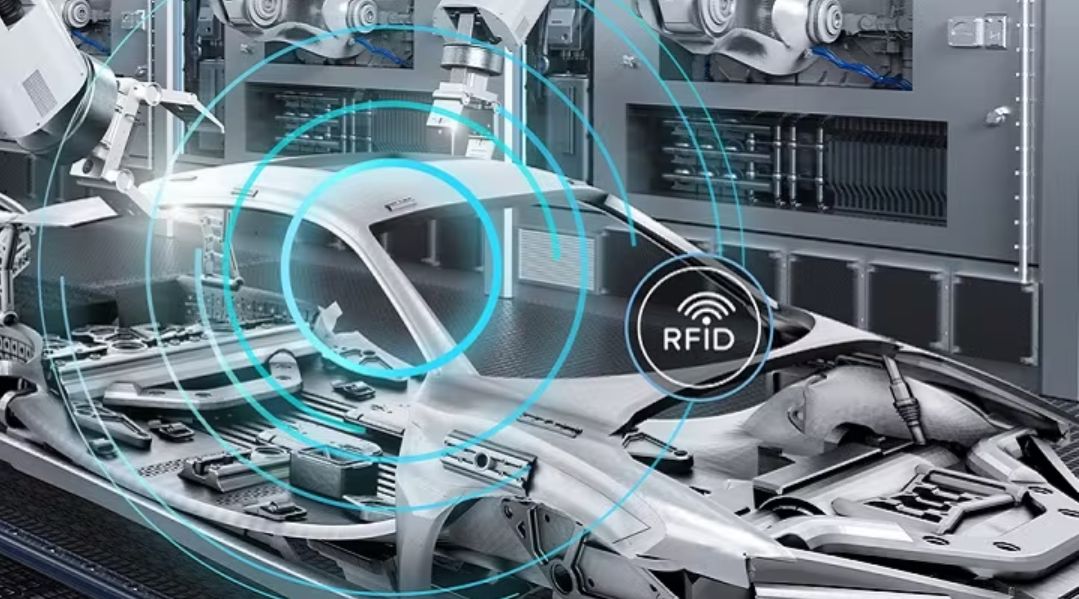

RFID is an innovative technology that involves embedding tiny chips in objects. The primary reason is to transmit unique identifiers to readers as they come within range. This simple technology has enormous implications for the automotive industry. It transforms every stage of the manufacturing phase from the assembly line to the open road.

- Production Line Efficiency: Imagine car components with embedded RFID tags gliding seamlessly through assembly lines, their every movement tracked in real-time. This level of visibility empowers manufacturers to make wise decisions.

- Enhanced Inventory Management: Say goodbye to manual stock counts and misplaced accessories. RFID tags embedded in car parts and accessories provide granular inventory visibility, making dealerships more efficient in several ways.

- Advanced Vehicle Tracking and Security: RFID tags, integrated into key fobs or embedded within vehicles, offer a robust security and tracking solution.

- Frictionless Car Access and Sharing: RFID-enabled keyless entry systems offer futuristic convenience, while similar technology can power seamless car-sharing experiences.

- Predictive Maintenance and Safety: RFID tags, paired with sensors, can gather valuable data on tire pressure, engine temperature, and component wear. This data, analyzed by AI, predicts potential failures before they occur.

8 Biggest Asset Tracking Trends

- Live Supply Chain Visibility

The automotive supply chain benefits from the unprecedented visibility RFID in automotive brings to the journey of components and finished products. RFID tags enable real-time tracking as components from many suppliers come together so that no part arrives too late or is degraded. The result is more fluid, efficient operations, less delay, and fewer errors in the supply chain.

RFID is an invaluable resource for maintaining the momentum of parts from the start of manufacturing to final assembly. If something falls behind or there’s an obvious bottleneck, it can be dealt with before production processes are affected.

- RFID Tags in Manufacturing

Using RFID technology in the automotive industry is a big deal. Manufacturers use RFID tags for their tools, equipment, and other components to monitor crucial details for optimal results. This exposure helps them collect live insights to make their production phase smoother, with less downtime and better efficiency.

In addition, automotive plants also utilize RFID tags to speed up their product manufacturing. It allows them to avoid excess inventory and predict when maintenance is needed. This approach helps manufacturers improve operations and contributes to long-term savings and sustainable measures.

- Organized Inventory Management

RFID technology is a robust tool for inventory control in the automotive industry. The traditional way of counting and tracking inventory was exhaustive and prone to human errors. With advanced technology like RFID, inventory management is automated and gives a fair idea about the auto parts stock and other available items.

Automotive manufacturers use this technology to monitor inventory levels and track the stock. One distinct feature that makes RFID for automotive a crucial consideration is the automated reorder process. This feature significantly reduces the risk of inventory stockouts or overstock parts by providing accurate data. As a result, it leads to an organized supply chain to enable automotive companies to handle market demands effectively.

- Streamlined Vehicle Lifecycle Management

RFID tags integrated into key fobs or embedded within vehicles offer a potent security solution. Real-time location tracking helps deter theft, locate stolen vehicles faster, and monitor unauthorized car movement. This empowers both dealerships and rental companies to protect their valuable assets.

During manufacturing, RFID tags help monitor the assembly process, ensuring that each vehicle is built to specifications. Throughout the vehicle’s life, RFID facilitates efficient maintenance by providing access to detailed service histories, enabling proactive maintenance scheduling, and reducing downtime.

- Enhanced Security and Anti-Theft Measures

Optimizing safety and ensuring compliance is critical for the automotive industry. RFID for the automobile industry provides auto-mated solutions to track and monitor valuable assets, including the raw materials of vehicle components and the vehicles themselves while on the production line. RFID tags are readable from great distances. This exceptional feature helps identify and avoid collisions and blockages, leading to greater productivity.

With advanced technology, vehicles now come with RFID-enabled keyless entry systems, with an RFID tag embedded in a key or fob. When the owner goes to open the door to the car, the tag sends an authorization signal to the vehicle. The vehicle verifies that the tag is coming from an authorized vehicle and allows the door to open if it is. The same thing happens when the car is started.

- Effective Fleet Management

Automotive companies manage a large fleet of vehicles. RFID technology enables smooth control over fleet management. Cars with RFID tags are easily traced. With these tags, it becomes easier to determine where they are, their usage and past repairs. This knowledge guides fleet managers to plan for repairs, select best routes, and use fuel wisely. RFID acts more than a vehicle tracker. It also records driver actions and checks that safety rules are followed, and firm rules are upheld. With RFID, firms can boost their operation, spend less on fuel, and make their vehicles last longer.

- Integration with IoT and AI

Integrating IoT and AI in RFID technology has revolutionized car asset tracking. This trend allows RFID tags to generate vast amounts of data with IoT sensors and AI algorithms. RFID tags flood us with lots of data. For example, RFID sensors can note down the environmental details while we move our sensitive car parts. It ensures that none of these parts face harmful situations. The AI formulas can then study this data, foresee any problems, and suggest ways to avoid these problems.

- Compliance with Industry Standards

The automotive industry needs to use standardized RFID solutions as it gets more interconnected. RFID technology meets industry standards for smooth integration at all car supply chain levels. By standardizing RFID in automotive, systems can work together and let manufacturers, suppliers, and service providers share data easily. It guarantees that RFID tags and readers from various brands can cooperate seamlessly. It supports a unified, standardized method to track assets in the car industry.

Implementing the Trends: Embracing the RFID Revolution

With such transformative potential, considering RFID technology is a strategic choice. However, navigating the vast array of technologies and applications can be challenging. Partnering with experienced RFID solutions providers becomes crucial to:

- Identify the right RFID technology: UHF tags for long-range tracking, HF tags for short-range applications, and even passive or active tags depending on power requirements.

- Design and implement a customized solution: Tailoring the system to your specific needs, whether it’s production line tracking, dealership inventory management, or driver personalization.

- Integrate with existing systems: Ensuring compatibility with your existing systems and software for an effortless transition.

- Provide ongoing support and maintenance: Professional expertise comes with dedicated customer support and maintenance services, ensuring the system’s longevity and maximum ROI.

Conclusion

The automotive industry is no stranger to innovation, but with the integration of RFID technology, it’s about to shift gears into a whole new era. From streamlining production lines to personalizing driving experiences, RFID unlocks possibilities, optimizing efficiency, enhancing security, and delighting customers. But navigating this exciting landscape requires a skilled navigator. Like a professional pit crew ensures a driver’s peak performance, Lowry Solutions empowers the automotive world with cutting-edge tools for seamless operation and optimized results. Take the next step towards revolutionizing your asset-tracking capabilities. Visit their website today and explore a world where RFID technology meets the future of the automotive industry.